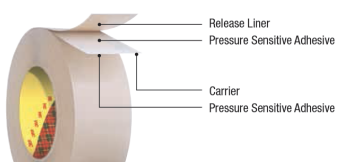

Double sided tapes provide high-strength bonding without mechanical fasteners. They use adhesive on both sides of a thin carrier. This delivers uniform stress distribution, improved aesthetics, and reliable performance on a wide range of substrates. Engineers and manufacturers rely on double sided tapes when they need consistent, repeatable adhesion solutions for plastics, metals, foams, composites, and textured surfaces.

Why Choose Double Sided Tapes?

Double sided tapes are used when a single adhesive layer is not enough. The carrier allows a controlled coating of two different adhesives, giving you the exact performance required for your application. Common advantages include:

● High shear and tensile holding strength

● Cleaner aesthetics compared to screws or rivets

● Precise gap filling and vibration dampening

● Ability to bond dissimilar materials with different surface energies

● Availability of dual-adhesive constructions such as acrylic/silicone or permanent/removable systems

These characteristics make double sided tapes ideal for mounting, splicing, laminating, converting, electronic assembly, point-of-purchase displays, signage, packaging, and print finishing.

Technical Specifications

Most double sided tapes use one of the following adhesive systems.

Acrylic Adhesive

● Excellent UV and solvent resistance

● Works on high surface energy (HSE) and many low surface energy (LSE) substrates

● Suitable for outdoor environments and elevated temperatures

● Higher shear strength for long-term static loads

Rubber Adhesive

● Very high initial tack

● Performs well on plastics, foams, and corrugated substrates

● Best for indoor, low-temperature, short-term applications

● Not recommended for UV exposure or solvents

Silicone Adhesive

● Bonds exceptionally well to silicone rubber and fluoropolymer surfaces

● Maintains adhesion at extreme temperatures

Carrier Options

● Tissue. Conformable, ideal for print finishing and light mounting

● Film/Plastic. Strong, dimensionally stable, suitable for precision assembly

● Foam. Provides gap filling, cushioning, and vibration dampening

Typical performance ranges include:

● Temperature resistance from 0°C to 150°C depending on adhesive chemistry

● Thicknesses from 2 mil to 60+ mil

● Compatibility with plastics, metals, painted surfaces, powder coat, foam, cardboard, and composites

Application Guide

Correct preparation is essential for maximising bond strength.

1. Prepare the surface

● Clean using isopropyl alcohol and a lint-free cloth

● Remove oils, dust, release agents, and residue

2. Check surface energy

● HSE materials like aluminium and glass bond easily

● LSE plastics like polyethylene may require an acrylic adhesive or surface primer

3. Apply with firm, even pressure

● Pressure activates the adhesive and increases wet-out

● Avoid repositioning once applied unless the tape is designed as removable/repositionable

4. Allow adhesive cure time

● Acrylic adhesives reach full strength in 24–72 hours

● Rubber adhesives reach strength more quickly but offer lower long-term performance

FAQs

Is double sided tape removable?

Some constructions use a permanent adhesive on one side and a removable or repositionable adhesive on the other. Acrylic adhesives are typically permanent. If you need removability, select a low-tack or specialty removable system.

Will this stick to powder coat?

Yes, but powder coat varies in surface energy. High-tack acrylic adhesives generally perform best. Clean the surface thoroughly and apply firm pressure.

Can double sided tape handle outdoor exposure?

Acrylic double sided tapes provide excellent UV, moisture, and temperature resistance, making them suitable for outdoor use. Rubber adhesives are best kept indoors.

What substrates work best?

Metals, glass, ABS, polycarbonate, and painted surfaces provide strong adhesion. LSE plastics may require a specific acrylic formulation or primer.